Core Considerations for Caster Chain Selection (3 Key Factors)

1.Material Matching Applications: Carbon steel (dry, light-duty environments like supermarket carts), stainless steel (humid/corrosive settings like food processing machinery), alloy steel (heavy-duty/wear-resistant applications like industrial conveyor systems).

2.Pitch and Dimensions: Chain pitch must match caster axle and drive gear pitch (common sizes: 6.35mm, 12.7mm). Chain plate thickness should be selected based on load capacity (≥3mm for heavy-duty applications).

Load Redundancy: Rated load ≥ 1.5 × actual total load (×2 for dynamic loads/frequent starts/stops) to prevent chain fatigue failure.

Application Scenario Recommendations

1.Light-duty consumer (shopping carts, trolleys): Carbon steel short-pitch roller chain, pitch 6.35-9.525mm, no rustproofing required.

2.Medium-load industrial (light conveyor lines, mobile workbenches): Stainless steel or galvanized carbon steel chains, pitch 12.7–19.05 mm, with anti-derail outer plates.

3.Heavy-load harsh environments (workshop heavy-duty carts, outdoor machinery): Alloy steel carburized chains, pitch ≥19.05 mm, maintained with grease lubrication.

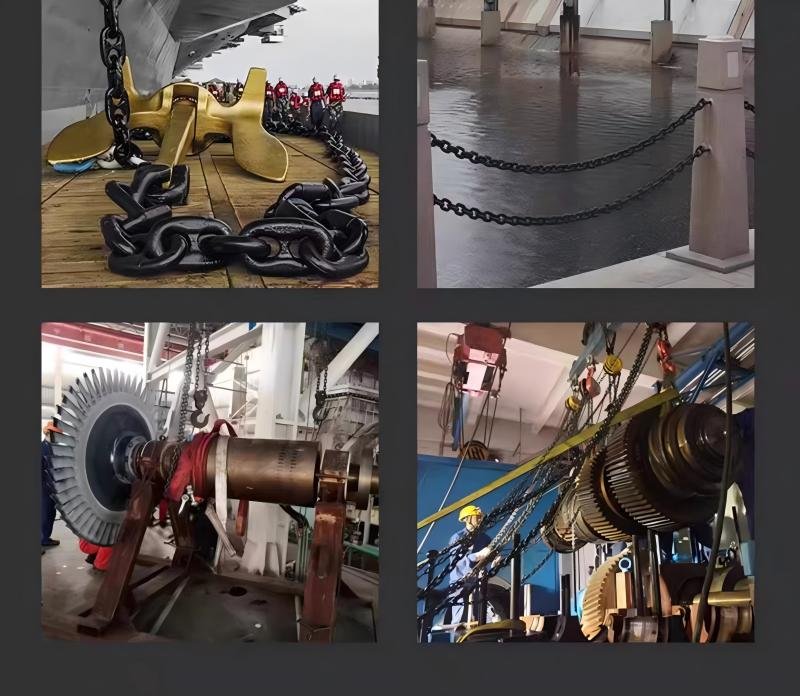

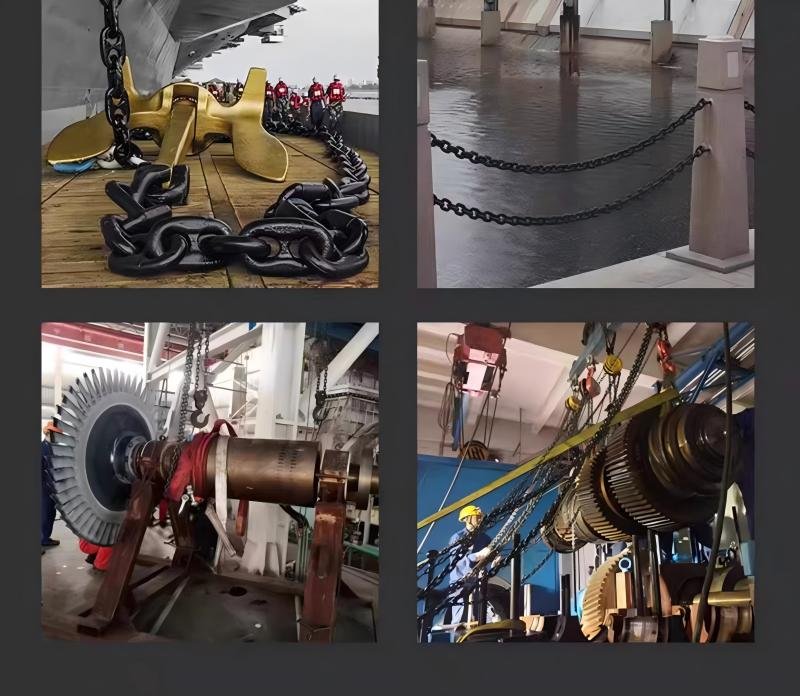

Caster Chain Application Scenarios Image

WHY CHOOSE US

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed Worldwide Marketing Network

7. Efficient After-Sale Service System

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve worldwide range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.