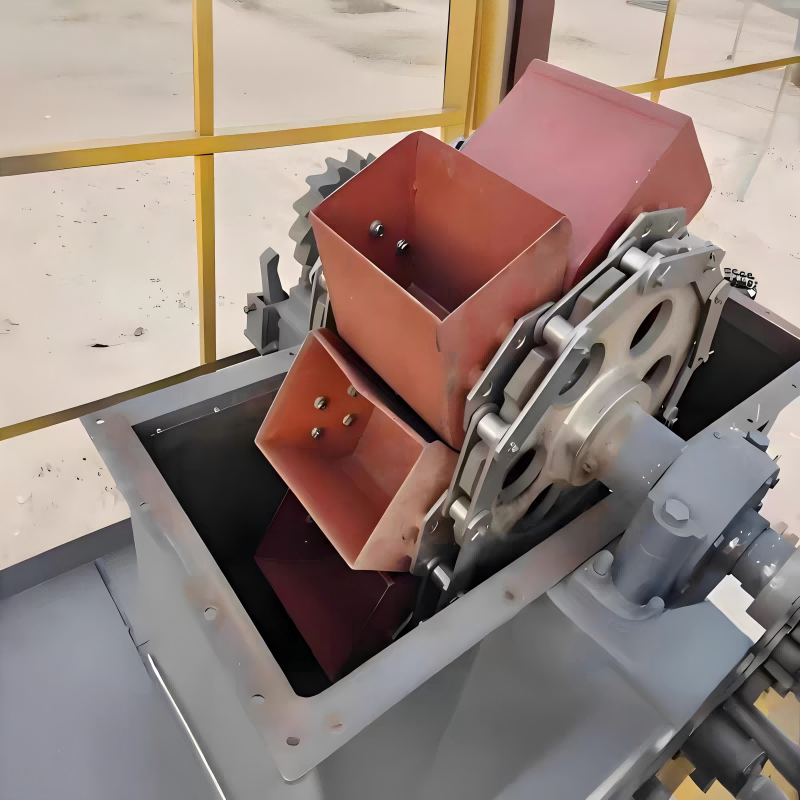

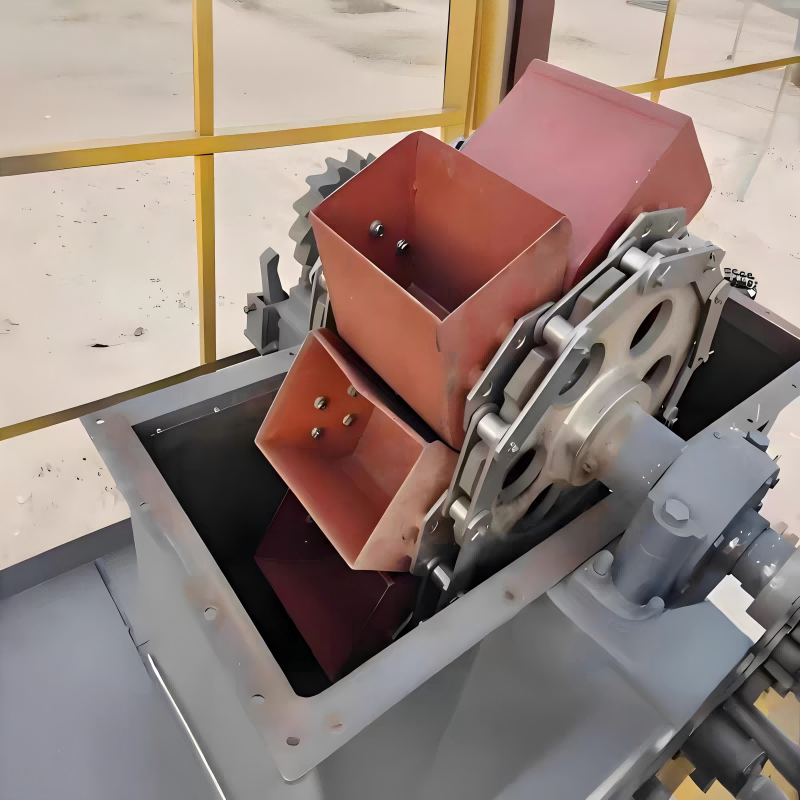

Chain Bucket Conveyor

Chain bucket conveyors, also known as trough conveyors, are devices that transport materials horizontally or at an incline using buckets running along tracks. They are widely used in power plants, mines, coal industries, and other sectors for conveying various bulk materials. Examples include boiler ash, cement clinker, slag, coke, crushed stone, and especially materials characterized by high temperatures, high bulk density, large particle size, sharp edges, and high abrasiveness. Chain bucket conveyors are highly favored by users due to their flexible layout, high conveying capacity, long service life, low maintenance requirements, low operating costs, and ability to operate at steep angles.

Working Principle

The conveying principle of chain bucket conveyors is as follows: the drive mechanism pulls buckets filled with material along tracks for horizontal or inclined transportation. Due to their advantages of flexible layout, high conveying capacity, long service life, low maintenance requirements, minimal operating costs, and steep conveying angles, chain bucket conveyors are widely used in power plants, mines, metallurgy, coal, and other industries for transporting various bulk materials. These include boiler ash, cement clinker, iron slag, blast furnace slag, limestone, crushed stone, and especially materials characterized by high temperatures, high bulk density, large particle size, sharp edges, and high abrasiveness.

Advantages

1. Flexible process layout: Can be elevated above ground or installed in a pit, mounted at an incline or horizontally. The entire unit can also be installed both horizontally and at an incline, ensuring safe and reliable operation with minimal vibration and noise.

2. Utilizes a drive mechanism, occupying a small footprint with simple operation and convenient installation.

3. The traction chain uses a plate-type design, offering high strength and extended service life.

4. The tail section incorporates a spring-spiral tensioning device that automatically adjusts chain tension.

5. Low energy consumption: The idler wheels in the load-bearing chain utilize rolling friction instead of sliding friction, reducing motion resistance and lowering the conveyor's traction force and power consumption. Separating the traction chain from the load-bearing chain simplifies the structure, reduces costs, extends service life, and minimizes wear on components.

6. High conveying capacity: Compared to similar equipment, conveying capacity can be increased by over 50%.

Installation and Trial Operation

Proper installation, debugging, operation, and regular maintenance are all essential to ensure the good performance of the chain bucket conveyor and are necessary measures to extend its service life.

Preparation and Inspection Before Installation

1. For all assembled parts delivered to the site, check for rust, damage, or other issues before installation. If any are found, they should be repaired, cleaned, and lubricated before installation is allowed.

2. The quality of key components such as chains must meet the requirements specified in the corresponding drawings.

3. Check whether the assembly of the chain complies with the requirements.

4. Check the rollers to ensure they can rotate freely. The installation positions of all parts and the quality of the rollers must be consistent with drawing specifications.

5. Carefully inspect and verify the measurement of positions at the installation site. The foundation dimensions of all devices and frames must correspond to those marked on the drawings. Any issues found should be addressed promptly, and all components should only be installed once all dimensions are confirmed correct.

Trial Operation

After installation, run the conveyor without load for at least 4 hours. Inspect the operating condition of all moving parts. The temperature rise of bearings and reducers should not exceed 30°C. During the load trial run, operate for at least 4 hours, and the temperature rise of bearings and reducers should not exceed 40°C. If the chain bucket conveyor meets the trial operation requirements, the machine can begin normal operation. If the trial operation requirements are not met, problems must be identified and corrected before restarting the machine.

Chain Lubrication Methods

The simplest lubrication method involves operators periodically applying oil to the chain using an oil can or brush. This approach is straightforward and convenient, though it tends to get hands dirty.

The second method involves using an oil cup to drip oil through an oil pipe into the inner and outer gaps of the chain. This is also a relatively simple and effective lubrication method.

The third method employs a sealed transmission housing. Part of the chain and sprockets are immersed in oil, and a large-diameter oil slinger is used to splash oil. This method tends to cause oil droplets to scatter around the area and is not recommended.

The fourth method employs an oil pump to continuously supply oil to the chain via tubing. This circulating oil also provides cooling, resulting in more pronounced lubrication effects. During chain transmission, the kinematic viscosity of lubricating oil at operating temperatures is 40 mm/s, indicating relatively high flow rates. Grease is only used as a lubricant when rotational speeds are low and oil supply is impractical.

Application Areas

This machine is suitable for conveying various powdery and lumpy bulk materials horizontally or at an incline ≤60°, particularly well-suited for transporting high-temperature, high-volume, large-sized solids with sharp edges and high abrasiveness. Chain bucket conveyors (chain bucket conveyors) are widely used in power plants, mines, coal industries, and other sectors for transporting diverse loose materials such as boiler ash, cement clinker, slag, coke, crushed stone, and especially materials characterized by high temperatures, high bulk density, large particle size, sharp edges, and high abrasiveness.