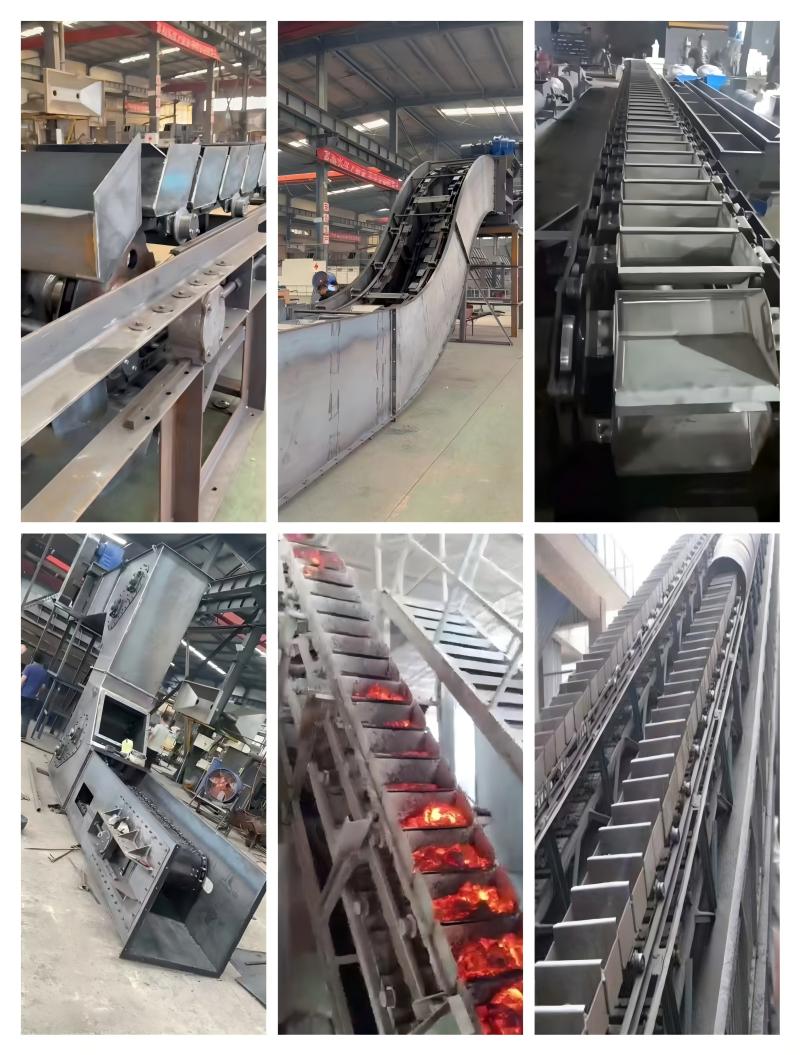

Core Structure (6 Key Components)

1. Drive Unit: Comprising motor, reducer, and coupling, this power core adjusts rotational speed based on conveying volume to regulate efficiency.

2. Traction System: Primarily chain-driven (for bulk/high-density materials) or belt-driven (for powders/granules), connecting and propelling buckets.

3. Bucket Assembly: Categorized by material properties into deep buckets (for dry granules), shallow buckets (for moist powders), and sharp-corner buckets (for sticky materials), typically made of stainless steel or wear-resistant plastic.

4. Conveying Track: Divided into horizontal, vertical, and turning sections. Track precision directly impacts operational smoothness; some models feature guide wheels at turns to reduce friction.

5. Enclosed Housing: Fully enclosed design, typically made of carbon steel or stainless steel, preventing material dust leakage, moisture ingress, or contamination. Some housings feature access doors for maintenance.

6. Discharge/Feed Device: Feed inlet equipped with an adjustable gate to control feed rate. Discharge outlet fitted with anti-surge baffles, supporting single-point or multi-point discharge to accommodate different production line requirements.

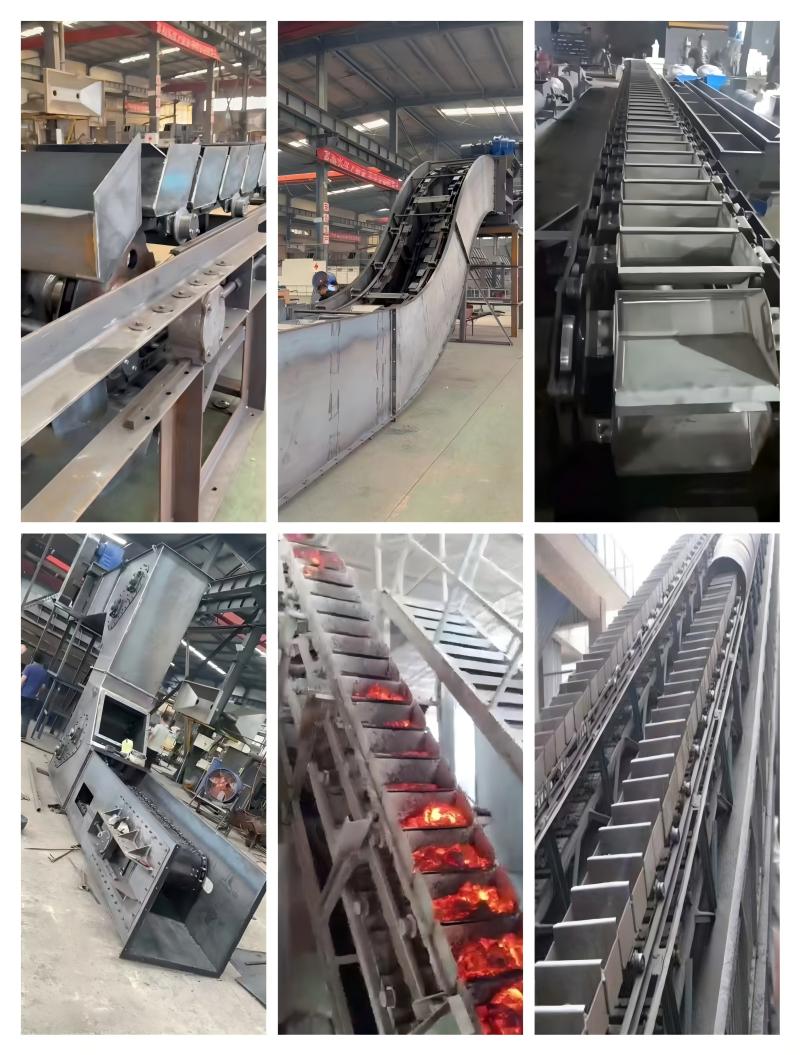

Workflow (4-Step Closed Loop)

1. Feeding Stage: Material enters through the horizontal section inlet. Flow is regulated by the gate to ensure uniform bucket loading (preventing overload or empty buckets).

2. Horizontal Conveyance: Material-filled buckets move along horizontal tracks via the traction system, completing position calibration before entering the vertical section.

3. Vertical Lift: Guided by deflection wheels, buckets ascend vertical tracks. Wear strips on the inner casing reduce bucket abrasion during this phase.

4. Discharge and Return: Upon reaching the top horizontal section, buckets redirect along the track. Material discharges via gravity or discharge scrapers to designated outlets. Empty buckets return along the opposite track for the next cycle.

Advantages

1. High Space Utilization: The Z-shaped trajectory replaces the “horizontal conveyor + elevator” combination, saving over 50% floor space and making it ideal for confined areas like workshops and warehouses.

2. Strong Environmental Performance: Fully enclosed housing design with dust leakage ≤5mg/m³, meeting hygiene standards for food, pharmaceutical, and similar industries.

3.Wide Conveying Range: Handles particles, powders, and small lumps (e.g., flour, plastic pellets, crushed ore) from 0.1 to 50mm in size, with a temperature tolerance of -20°C to 120°C.

4.Stable Operation: The traction system employs an automatic tensioning device for self-adjustment, resulting in low failure rates and a Mean Time Between Failures (MTBF) exceeding 8,000 hours.

Application Areas

The Z-type bucket elevator is suitable for use in the food industry, puffed food industry, feed industry, confectionery industry, dried and fresh fruit industry, health food industry, grain processing industry, chemical and pharmaceutical industry, hardware and electrical materials industry, and military manufacturing industry. It is ideal for conveying powdered and granular materials, as well as non-sticky materials such as grain, feed, cement, crushed ore, and similar substances.

Bucket elevator application fields

Why Choose Us?

1. Reliable Quality Assurance System

2. Cutting-Edge Computer-Controlled CNC Machines

3. Bespoke Solutions from Highly Experienced Specialists

4. Customization and OEM Available for Specific Application

5. Extensive Inventory of Spare Parts and Accessories

6. Well-Developed Worldwide Marketing Network

7. Efficient After-Sale Service System

We are not just a manufacturer and supplier, but also an industry consultant. We work pro-actively with you to offer expert advice and product recommendations in order to end up with a most cost effective product available for your specific application. The clients we serve worldwide range from end users to distributors and OEMs. Our OEM replacements can be substituted wherever necessary and suitable for both repair and new assemblies.